Seedy Multi - Self-propelled experimental plot seeder

Seedy multi is a state-of-the-art self-propelled experimental asparagus planter

Machine has traction on all 4 wheels, small turning radius. 4 cyl. Kubota diesel engine.

Modern operator station with joystick to control machine functions

Computer to control 2 Amazone seed boxes and Flexiseeder seeding equipment

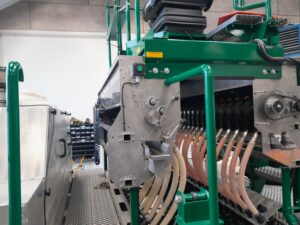

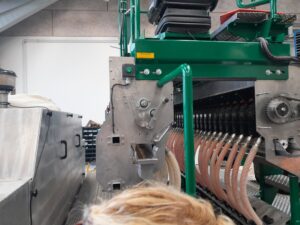

Forrest 10 Amzone portable disc coulters for fertilizer

In the middle 20 amazone Twin tec coulters with built-in after harrow

Rear 20 S-M-V Seed coulters with depth wheel

2 Amazone seed boxes with electric drive controlled by computer and measuring wheel. automatic seeding by activating a seeding button.

Automatic dosing with preselection on computer

Flexiseeder 400/280 mm cellular wheel seeder with electric drive. All settings plot length spinner speed mm are adjusted from the driver's seat

Many different outlet heads for different row counts are available

Possibility for to move outlets from the seed drills around to the different coulters.

Option for GPS control and signal for triggering a Flexiseeder.

Materials: Steel and aluminum

Length: 5 meters

Width: 3.15 meters

Height: 3.85 meters

Track width: 2.5 meters center - center

Wheelbase: 4 meters

Wheels: 8.5×24″ 1000 mm high 210 mm wide

Engine: Kubota 4 cyl diesel 48 Hp.

Hydraulic drive on all 4 wheels, as well as locking between for and rear wheels.

Compressor for operation and cleaning of seeding equipment and operation of liquid sprayer/fertilizer equipment

Lighting systems for driving on the road

Modern operator platform with air suspension seat, joystick for operating the machine, plus computer for operating all 3 seeders.

Fertilizer coulter: Amazone Rotech single disc coulter with depth limiter

Coulter: Amazone Twintech double disc coulter with depth wheel and harrow tooth

Seed coulter: SMV adjustable coulter with depth roller.

Seed boxes: 2 SMV/Amazone seed boxes with electrical operation of the seed roller controlled by computer, with impulses from measuring wheels. Very accurate seeding

Electric seeding at the push of a button. Preselection of 7 seeding rates

The seed boxes are incredibly easy to operate. Switching handle between seeding and unseeding. Fixed seeding tray, always ready for seeding.

Tilt the seeding handle, press the seeding button, weigh the material in the seeding tray, enter the quantity into the computer and the machine is ready to use

Up to 7 Kg/hectare presets can be freely selected during operation

The seed rate from both seed boxes can be fed to all 3 rows of coulters by easily moving hoses around the center of the machine

Variable number of seed rows simply by closing for the individual shutters to the seed wheels.

Large and small seed wheels in the same housing. Simply close for the shutter of the wheel you do not want to use.

Bagger: Flexiseeder Multi cell wheel unit with the option for of 400 and 280 mm cell wheels in the same unit. The cell wheel is easily replaced.

Electric spinner with variable speed. Many different outlet heads can be mounted. From 6 - 20 outlets.

The Flexiseeder unit is controlled by the computer where the parcel length is entered and the measuring wheel gives impulses to the computer which controls the cell wheel very accurately.

The seed volume from the flexiseeder unit can be fed to all 3 rows of coulters by easily moving hoses around the center of the machine.

Good working platform with electric seed rate release.

Horn switch to warn the driver

Air suspension seat with great comfort

Compressed air system: the machine is equipped with compressor and air tank for air system.

Compressed air precision regulator, for spraying / fertilizing function.

Blow guns placed strategically to clean the different units.

General: The machine is equipped with mechanical markers, but can also be equipped with many different brands of GPS equipment.

GPS The equipment can also be connected to the Flexiseeder's release function, freeing the operator for from this work.

Good access routes with ladders, handrails etc. to ensure safe access to the machine